New tech to watch: three products improving lung transplants, seizure prevention, nanoprobing

Published: June 8, 2015

Watching a lung transplant at Toronto General Hospital five years ago, alumnus Geoff Frost noticed a problem: keeping lungs alive outside the body requires large, cumbersome machinery that monopolizes hospital space.

“It takes up an entire operating room,” says Frost, an alumnus from both U of T's Institute of Biomaterials and Biomedical Engineering and Faculty of Applied Science & Engineering.

Frost says the cost of current technology, plus training for its technicians, racks up thousands of dollars per hour in Canada.

A smaller, simpler system could increase the number of lungs transplanted since it could be installed in more places and used more often.

Frost (pictured at left) pitched the idea to his graduate supervisor, Thomas Waddell, head of thoracic surgery at University Health Network, and the two co-founded XOR Laboratories Toronto Inc. to transform their idea into practice.

Frost (pictured at left) pitched the idea to his graduate supervisor, Thomas Waddell, head of thoracic surgery at University Health Network, and the two co-founded XOR Laboratories Toronto Inc. to transform their idea into practice.

Since 2014, Frost has dedicated himself full-time to developing a mobile, dishwasher-sized prototype ex vivo lung perfusion machine – the device keeping lungs alive outside the body – that performs to industry standard.

He says the mobile prototype, which he hopes to complete within two years, could also play a role in organ storage by replacing the current practice of storage on ice.

Frost is one of three innovators from U of T working to bring products to market with the support of a Heffernan Commercialization Fellowship.

First established in 1997 by entrepreneur and engineering alumnus Gerald Heffernan, the commercialization fellowships continue to enable graduate students to turn their research into viable businesses. In 2014, Heffernan renewed the program as part of a $5 million gift to the Faculty that also provided support for the upcoming Centre for Engineering Innovation & Entrepreneurship (CEIE).

Stopping seizures before they start

More than 100,000 Canadians suffer from uncontrolled seizures due to epilepsy. Some have found relief with devices implanted under the skin that electrically stimulate the vagus nerve by firing at regular intervals.

However, these devices sometimes miss seizures since they can't predict when an episode might occur.

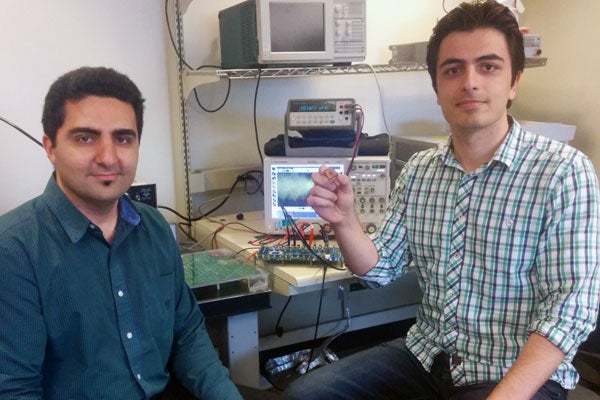

Hossein Kassiri and Nima Soltani (both PhD candidates in electrical and computer engineering) have a solution. Their device – an implantable chip connected directly to the brain via an electrode – integrates components that both stimulate nerves and read and interpret their signals. Aided by a sophisticated decision-making algorithm, the device can detect the earliest possible signs of a seizure and provide appropriate stimulation, often before the user is even aware of what’s happening.

Kassiri and Soltani are using the fellowship to produce prototypes and fill requests for the devices from research labs worldwide. They expect the tests to confirm the safety and effectiveness of the implants, which in turn will help secure the regulatory approval needed to start manufacturing the product on a commercial scale.

Testing nanoscale devices

A computer chip contains billions of nano-sized integrated circuits; a flaw in any one of them could spell doom for the entire chip.

The only way to ensure quality control is ‘nanoprobing’, which involves using tiny robotic arms to make direct measurements on each circuit.

U of T mechanical engineer Brandon Chen has developed an advanced manipulator system (pictured at left) that could greatly speed up this task.

U of T mechanical engineer Brandon Chen has developed an advanced manipulator system (pictured at left) that could greatly speed up this task.

Working in the lab of Professor Yu Sun of mechanical and industrial engineering, Chen developed sophisticated control algorithms that can automate the movements of the robotic manipulators, eliminating the dependency on the skills of a human operator.

“Our technology has demonstrated at least a 10 times increase in nanoprobing speed compared to the state-of-the-art systems used in the industry,” he says.

Already attracting the attention of the leading semiconductor manufacturers, Chen’s company, Toronto Nano Instrumentation Inc., has purchase orders in the queue. He will be using the Heffernan Commercialization Fellowship to fund some final improvements, safety certification and prepare demonstration products for future customers. Chen expects an official product launch later this year.