Undergrads, professors collaborate to develop state-of-the-art leg brace for student with cerebral palsy

Published: August 27, 2015

Robotic exoskeletons have long been a staple of science fiction.

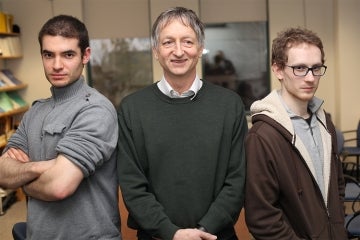

Now, Master of Information student Thomas Garside has collaborated with iSchool Professor Matt Ratto and a team of Engineering students and motion specialists from the Faculty of Kinesiology & Physical Education to make such a device a reality.

A full-time student concentrating on critical information policy studies and knowledge management, Garside has limited mobility because of cerebral palsy. Normally he gets around with a cane, wheelchair or motorized scooter.

When he arrived at U of T, he knew that more advanced mobility aids were under development – and that their price put them out of reach.

Garside was also familiar with Ratto’s work as director of the iSchool’s Critical Making Lab, and in particular his application of 3D printer technology to the problem of producing prosthetic sockets and limbs for Ugandan children.

“Even before being accepted into the iSchool I was impressed by the work he had done,” Garside says.

The student decided to approach his professor of only two months about the possibility of creating a powered assistive device to help him, and others with mobility challenges, walk better.

After consulting iSchool Dean Seamus Ross, they enlisted final-year engineering students Shakthi Seerala, Lakmini Perera, Kayatri Rangarajan and Elizabeth Sumitro to work on the electrical controls and sensor systems necessary for a mechanized leg brace.

The circle of collaborators continued to widen: Garside sought out the expertise of Professors Luc Tremblay and Tyson Beach, sensorimotor control and biomechanics specialists from the Faculty of Kinesiology & Physical Education. Using state-of-the-art 3D motion-capture and force-measurement systems, Beach analyzed Garside’s gait.

Meanwhile, the Tetra Design Group charity connected Garside with a volunteer who was able to fabricate the mechanical components of the brace. Using off-the-shelf radio-controlled motors, the Engineering team finished a functioning prototype at a cost of only $1,000.

Meanwhile, the Tetra Design Group charity connected Garside with a volunteer who was able to fabricate the mechanical components of the brace. Using off-the-shelf radio-controlled motors, the Engineering team finished a functioning prototype at a cost of only $1,000.

Last spring Garside got to strap on the result of all this multi-disciplinary hard work. The prototype works by measuring the pressure exerted by the foot, detecting what part of the stride cycle he is performing and helping him flex his leg to complete the appropriate movement.

“I have been amazed by the quality of the brace,” Garside says. “And I have been delighted to see how well the Master of Information program can help in the development of physical devices. The training I’ve received on design from faculty like Colin Furness has really been well applied to hardware.”

Apart from enhancing his mobility, the project has given Garside useful experience in project management.

The next steps are to work with Engineering and Tetra to improve the brace’s control system and look at different structural materials. Then, create a brace for his left leg.

The results of this collaboration could have worldwide impact.

“Besides the enhancement of the prototype,” Garside says, “we’re all excited to continue to show the world that exoskeleton technologies are now mainstream technologies capable of solving issues of mobility for the disabled and elderly.”