U of T Engineering students build smart, sterilizing UV lamp to fight COVID-19

Published: October 7, 2020

Bipasha Goyal is creating what she hopes will be the newest line of defence against the global COVID-19 pandemic: a smart UV lamp.

“Hospitals already use a similar method called ultraviolet germicidal irradiation (UVGI) to sterilize operating theatres and other spaces,” says Goyal, a third-year engineering science student in the University of Toronto’s Faculty of Applied Science & Engineering. “The challenge is that these systems are very expensive, and it’s hard to ensure a sufficient UV dosage has been applied to a surface.”

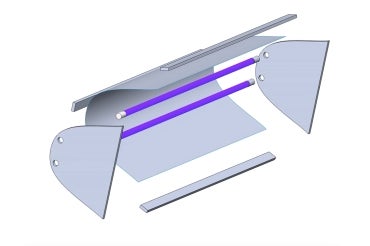

Goyal and her colleagues on Team LumineSence – which also includes Joyce Poon, a professor of electrical engineering, and several fellow U of T Engineering students – are designing a new UVGI system that would be more effective and less costly than currently available machines. They are focused on both the light emission and light sensing aspects of the device.

“Much of the innovation in existing systems has been the autonomous mobile robot supporting the lamps,” says Goyal. “But when it comes to the lamps themselves, the emission pattern is usually not shaped or purposefully directed. The lamps have not been integrated with any sensors to monitor their efficacy.”

Team LumineSense is creating an integrated system that would eliminate this shortcoming and could be mounted on mobile racks, ceilings or tabletops. The team and its flagship product sprung from CDL Recovery, a program run by the Creative Destruction Lab at the Rotman School of Management that focuses on smart solutions to accelerate the world’s recovery from the COVID-19 crisis.

Using smart sensors and carefully designed algorithms, the device would adapt its output to provide optimal UV light exposure to sterilize surfaces. The sensors would also enable it to automatically shut down if human presence is detected, minimizing the risk of exposure to harmful UV radiation.

Currently, Goyal’s contribution to the project is being supported by a Mitacs Research Training Award, which is being matched by U of T Engineering. She is among 87 U of T Engineering undergraduate and graduate students whose research projects have earned the awards, with projects ranging from data science and artificial intelligence to advanced materials and manufacturing.

Many of the projects also involve partner organizations. In Goyal’s case, it’s the Max Planck Institute (MPI) of Microstructure Physics in Germany, where Poon serves as director. Early in the project, MPI researchers brought new ideas, advice and insight to LumineSense.

“Communicating with a large team across multiple time zones was a difficult task,” says Goyal. “It taught me the importance of being in regular communication and seamlessly distributing roles and responsibilities.”

“As engineers, we contribute to solutions to better the world,” says Poon. “I am very proud of Bipasha and all of the students and postdocs who have come together for this team project.”

In addition to enhancing her technical understanding of light sensing and autonomous robotics, Goyal says the project is also teaching her about the challenges of translating research from the lab to the marketplace.

“The overall features and use cases of the design required us to identify potential stakeholders, which include schools, research labs and even residential buildings, and create an adaptable modular design to better suit their needs” she says.

“COVID-19 affected everyone professionally and personally. I consider myself very lucky to have found this opportunity to be involved in such a meaningful project.”